Qualification & Validation

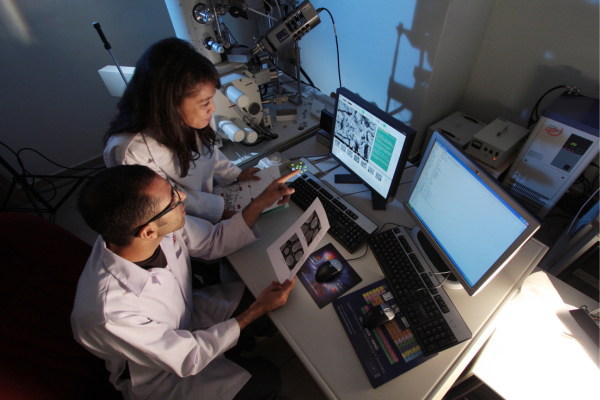

QbD offers a wide range of qualification & validation services for your processes, applications, and equipment. We guarantee that your products meet quality demands and comply with regulations.

Our efficient and well-structured risk-based approach provides the right focus to ensure that your biotech products meet high-quality requirements and regulations, and demonstrate that they are properly prepared, packaged, labeled, and traceable.

Our Qualification & Validation services

Equipment Validation

Need a turnkey solution for the C&Q and Equipment Validation part of your project? QbD offers a flexible and customized solution!

Process & Cleaning Validation

Our qualification & validation experts are pleased to set up, improve and support the qualification & validation of your processes and cleaning.

Environmental monitoring

Quality by Design invested in state-of-the-art equipment and is happy to assist you with environmental monitoring services.

Software validation remains as critical as ever, from automation and digitization to AI and machine learning. Our CSV experts are happy to help!

Commissioning

Commissioning is crucial for getting your systems and equipment to perform at their best and be safe across industries.

Sterilization Validation

We specialize in comprehensive Sterilization Validation services made for your specific industry and regulatory requirements.

Process & Product Support

Working with QbD Group, you can trust that your processes and products will receive the support and guidance needed to excel in today’s competitive marketplace.

At QbD Group we offer Facility & Utility Validation services tailored to your specific industry and regulatory requirements.

Cleaning Validation

At QbD Group, we can rely on your analytical methods being validated to the highest standards, providing confidence in your test results, and supporting informed decision-making!

Analytical Method Validation

Need a turnkey solution for the C&Q and Equipment Validation part of your project? QbD offers a flexible and customized solution!

Tech Transfer

Our experienced QbD Group team offers comprehensive support, from technology evaluation and documentation to process optimization and training, ensuring a smooth transition and successful implementation.

Why QBD Group?

QbD supports companies worldwide in the life sciences throughout the entire product lifecycle, from idea to patient.

With more than 450 quality experts, QbD is your partner for advice and support on controlling quality risks.

10+ years of experience

Full life cycle support

Global presence

Best Managed Company

Contact us

Need help with your Qualification & Validation? Don’t hesitate to get in touch.